YAG laser welding machineIs the use of high-energy pulse laser welding of the workpiece, it is pulsed xenon lamp as a pump source to ND: YAG as a laser working material. Laser power first pulsed xenon lamp pre-combustion, through the laser power to the pulse xenon lamp discharge, so that xenon lamp to produce a certain frequency and pulse width of light waves, light waves through the condenser cavity irradiation ND: YAG laser crystal, which excites ND: YAG laser crystal to produce laser, And then through the cavity after the wavelength of 1064nm pulse laser, the laser beam through the beam, reflected (or after fiber transmission), after focusing radiation to the workpiece surface, the workpiece local melting to achieve welding.

The frequency, pulse width, table movement speed and moving direction of the pulse laser required for welding can be controlled by PLC or industrial PC, and the laser energy can be controlled by adjusting the size of the current, the frequency of the laser and the pulse width.

|

Features: |

1: high aspect ratio. Weld deep and narrow, bright and beautiful weld.

2: Due to the high power density, the melting process is very fast, the input workpiece heat is very low, the welding speed is fast, the thermal deformation is small and the heat affected zone is small.

3: high density. Welds in the process, the pool constantly stirring, gas escape, resulting in no holes through the weld. After welding high cooling rate easy to weld microstructure, weld strength, toughness and comprehensive performance.

4: strong welds. High temperature heat source and the absorption of non-metallic components to produce a purification effect, reducing the impurity content, changing the size of the inclusion and its distribution in the molten pool, the welding process without electrode or filler wire, the melting zone is small, Seam strength, toughness is equivalent to even more than the parent metal.

5: Precise controlThe Because the focus spot is very small, the weld can be positioned with high precision, the beam is easy to transmit and control, and it is not necessary to change the torch and nozzle frequently. It can significantly reduce downtime and high production efficiency. Light without inertia, you can also stop at high speed and start again. With the control beam movement technology can be welded complex components.

6: non-contact, atmospheric environment welding. Because the energy comes from the laser, the workpiece has no physical contact, so no force is applied to the workpiece. Magnetic and air have no effect on the laser.

7: Due to the low average heat input, high processing precision, can reduce the processing costs. At the same time, laser welding operation costs lower, can reduce the cost of the workpiece.

|

Industry Application: |

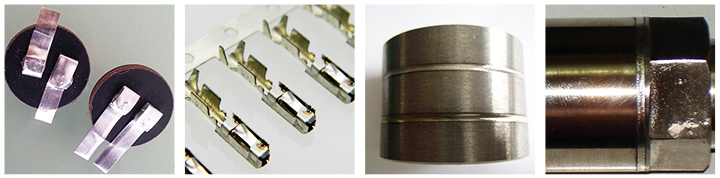

Automotive parts industry: engine cylinder pad; hydraulic tappet seal welding; filter seal welding; spark plug welding; valve putter welding; anti-collision airbag electric tube sealing welding; crankshaft or cylinder heat treatment;

Electronics industry: cell phone batteries, power battery shell seal welding; solid state relay seal welding; connector data cable welding;

Hardware industry: tools, accessories, tableware, lighting; and so on

| Product parameters: |

| machine type | CY-A200-2D/3D/4D |

CY-A200-2D/3D/4D |

CY-A200-2D/3D/4D |

| Laser power | 200W | 400W | 600W |

| Laser wavelength |

1064nm |

||

| Laser working medium |

ND:YAG |

||

| Frequency Range | 1Hz-200Hz | ||

| Spot adjustment range | 0.1mm-3mm | ||

| Pulse Width | 0.1ms-20ms | ||

| GPS | CCD/Red light | ||

| Total power | 6KW | 8KW | 10KW |

| Machine weight | 230kgs | 270kgs | 270kgs |

| Operating temperature | 15°C-35°C | ||

| Power supply requirements | AC220V 50Hz | AC380V 50Hz | |

| Samples: |